Why do you have to focus a laser?

Yes, why?

Lasers are those famously parallel beams of light that go on forever right? Well sort of and in many cases they’re fantastic for measuring, line-of-sight comms links and all sorts of other stuff. If you have a laser level in your DIY box you’ll immediately get this.

So why does it need to be focused?

To cut/engrave material you need to direct all the energy of the beam into a really small spot. This is directly analogous to using a magnifying glass to burn a hole in paper on a sunny day. With the magnifying glass, say a 10cm round one, when you focus the sun onto that little dot you’re taking that 10cm of energy and putting it all onto a 1mm dot on the paper. That’s 7854mm2 of sun condensed onto 3.1mm2, a 2500x increase in energy for the area. When you see it put like that you can see why the paper burns!

It’s the same principle

Likewise with a laser you want the smallest spot you can get. Concentrate all the energy into that dot to get a nice, fine cutting edge or great resolution for engraving.

A typical laser dot is around 0.08-0.1mm in diameter but the beam from the laser tube itself is around 10mm in diameter so a lens is used to focus that into a spot of 0.1mm. Unsurprisingly this cuts and engraves very well!

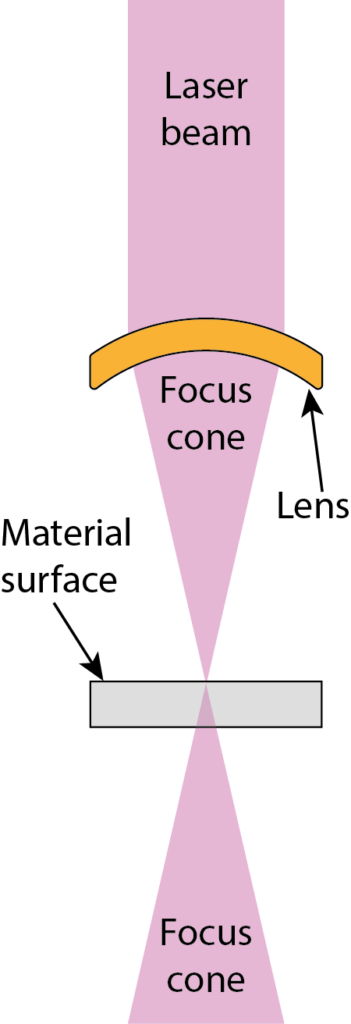

When engraving you want to focus the beam onto the surface of the material. if you’re cutting, particularly on thicker material like 12 or 18mm MDF, you want to focus the beam a little below the surface. Why is this you ask? A simple diagram will explain! As you see, because the beam is focused it’s now a cone shape which means the power for the area varies outside of the focal point. If you focused on the surface of the 12mm MDF your beam would be out of focus by quite a bit on the underside of the material.

By moving the focus closer to the centre of the material you’re a little out at the surface and the underside still, but far less than you would have been overall by focusing on the surface. You also get a slightly straighter edge to the cut overall due to the ‘cone’ of the laser being narrower across the depth of the cut. For regularly cutting thicker materials you can actually use a different lens with a longer focal length which gives you a narrower cone (but slightly lower engraving quality). This also allows you somewhat greater positioning freedom when you want to focus lower into the material as a standard lens only gives you about 4mm freedom with the focus before it bumps into the surface.

We hope you found this interesting (and maybe even useful) – now you know why lasers sometimes need to be focused! Take a moment to see how this understanding is used to create the great things we make in our gallery and of course always make sure to get in touch if you have something that you’d like created.

Have something you need to create and have an idea of the material and budget for it? Fill out our short quotation form to get an idea of cost!

If you have an idea for something you’d like created but not sure if it can be done or you’d like a longer discussion about any questions you have then get in touch!

Leave a Reply