Focus on slate

Here we will be dealing with laser engraving slate and what you can’t do to it with a laser.

You can’t cut it. Well you possibly can if you have a hugely powerful industrial laser. For all intents and purposes all you’re going to do with slate is mark it. Which is fine, slate looks very smart when you mark it with a laser. In the above picture the mounting holes were marked with the laser and drilled with an 8mm diamond tile bit.

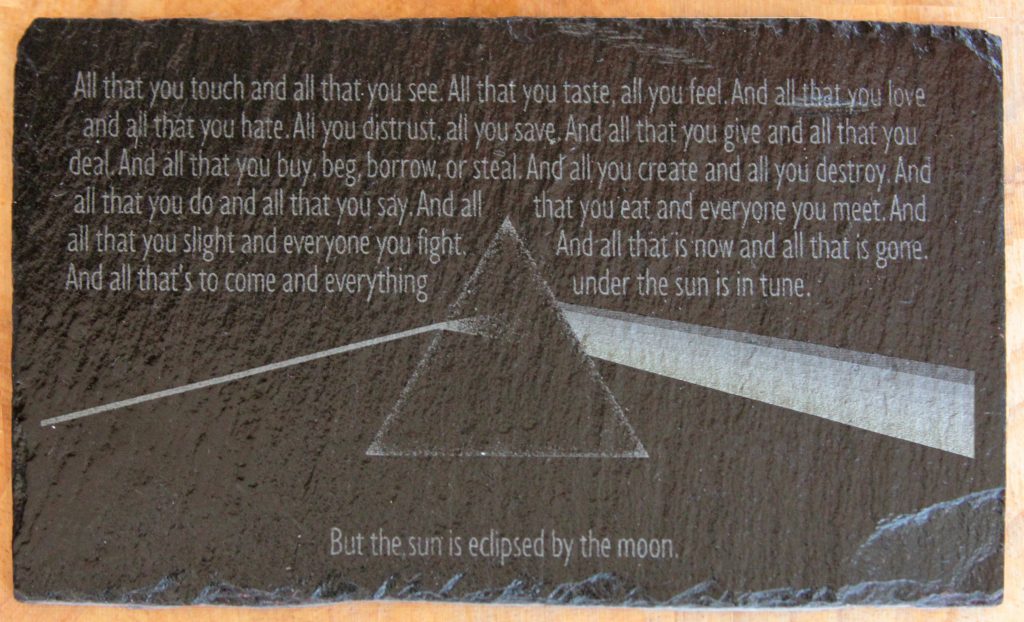

You can do colour. Sort of. When marking slate there’s a transition of colour over a short period of time which you can control with the laser power for a given speed. The marking changes from grey to light grey to almost white to yellowy-white to a yellow-gold colour. This allows for the possibility of differently-coloured outlines to text and other sections of the slate, giving varying tone to the marking. In the Dark Side of the Moon slate above this is employed in the rainbow on the right hand side of the prism.

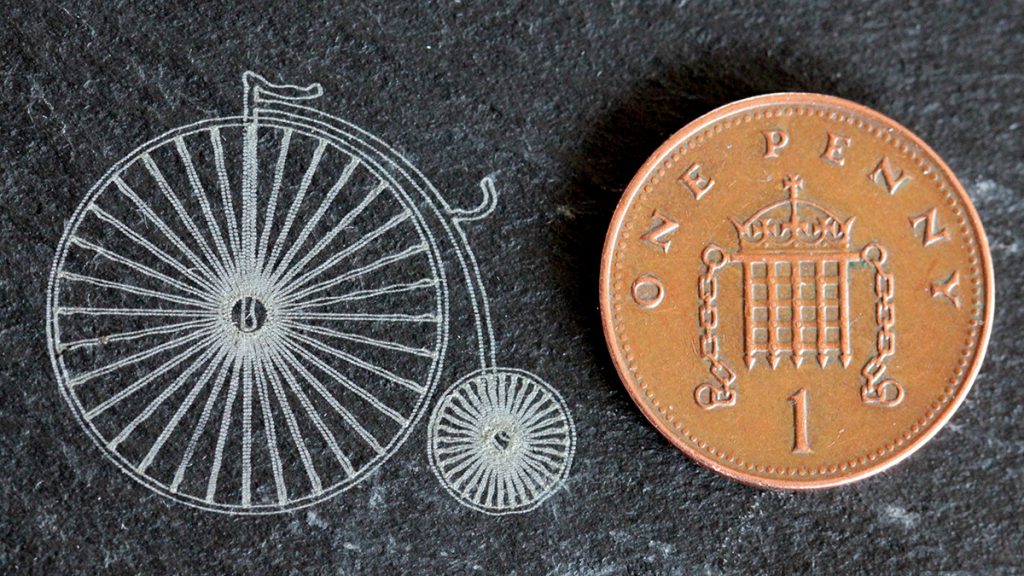

It’s high resolution. When engraving wood or other ‘organic’ materials like wood the laser will create a small scorch area around its intended area. If you think of a single dot it won’t be perfectly burnt/not-burnt, there will be a small transition zone between the two states. Slate doesn’t suffer from this to the same degree so you can get finer detail. This, of course, is great for printing images and with a careful combining of power settings and dithering you can get some excellent results.

It doesn’t smell. Most materials smell when lasered (it’s heat, after all, you’re burning it). Some, like acrylic and laser rubber, really smell. Allegedly deer antler is awful! Slate has no discernible smell at all. Which is nice.

The finish. We provide two lacquered finishes for slate, matte and gloss. It’s not quite as straightforward as picking printer paper or paint, though so we made a short video clip so people can see the difference for themselves.