Most laser cutting or engraving machines work in 2D which is to say the laser generally fires downwards from above the material. In the case of a plotter style laser the laser beam is moved around on an X and Y axis on rails with mirrors, hence the ‘plotter’ label. With galvo lasers the beam is redirected from the head by a pair of X-Y mirrors, using a galvanometer hence the label ‘galvo’. Some galvos have ‘3D’ heads but that only means that it has a third axis in the head which adjusts the beam focus to allow for materials with varying heights like curved objects.

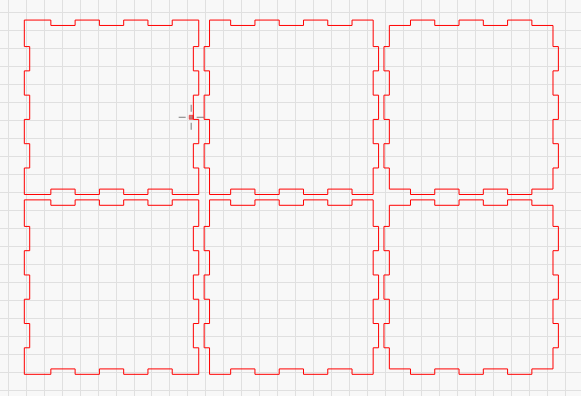

If you think of flatpack furniture, that famous Swedish company, say, then your shelving unit didn’t come as a great big 6-foot by 6-foot box, it came, probably, in a 6-foot by 1-foot box and you had to assemble it. It’s a similar principle with lasered items – you create the components then assemble them. Take our Hellraiser box, for example, that’s made from one sheet of 3mm ply or MDF and one sheet of 0.8mm ply like this:

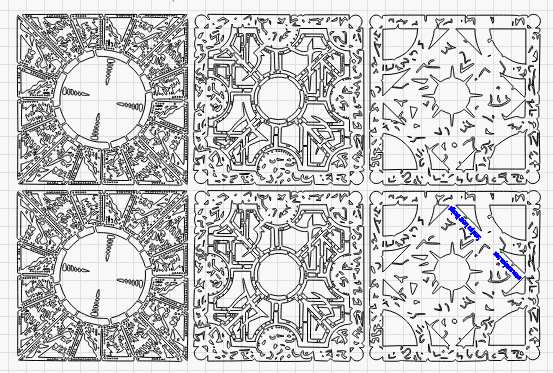

As you can see, this assembles into a cube. The surface design is laser cut as six panels from 0.8mm ply to make panels for the faces:

Some paint and glue – you get the idea – and voilà!

Another approach is to slot items together. If you’ve ever made one of those little glider toys which are so often sold at holiday resorts in the UK then you’ll immediately be familiar with this. When made correctly they need no glue and slot together snugly to create the finished item. Here’s a ‘Flatapult’, so called because it’s laser cut from a flat sheet of ply with tabs to hold the parts in place which can be pressed out of the sheet and assembled into a functioning catapult for flinging ping-pong balls across the room (or maltesers!).

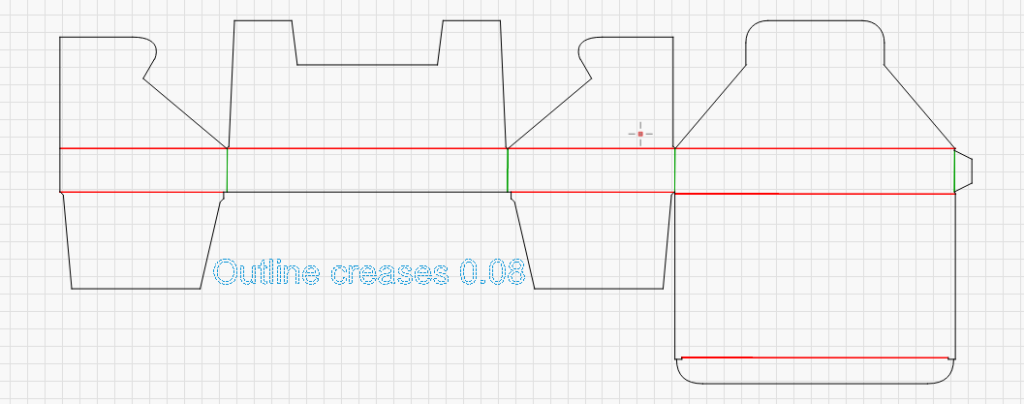

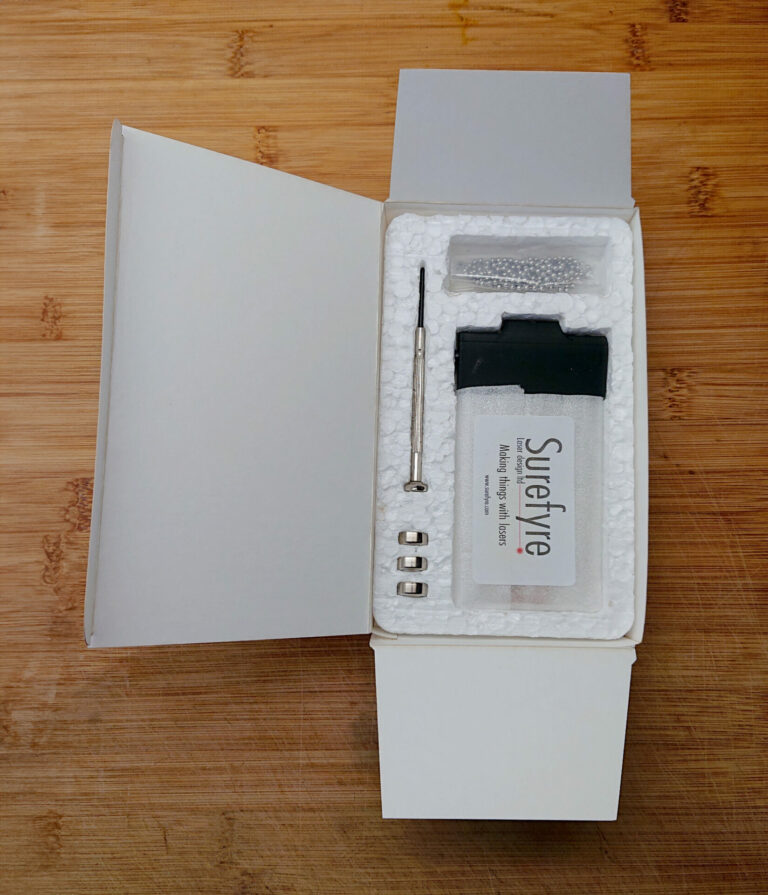

Lastly one hugely common method is the dieline, used all over the world for boxes, typically. If you’re the one in your house who does the recycling you may well be familiar with this – when you ‘unassemble’ a cardboard box to flatten it you’ll notice how it’s often all one piece, cleverly designed to fold and fit together into a box. The pattern for this folding box shape is called a dieline and there’s many different types as you might guess. We use dielines to create our own boxes, our GlowTags for example, which we use to both cut the paper/card and, with the laser on lower power, score the lines for easy folding. The dieline design holds itself together and only a tiny piece of double-sided tape in one corner is needed to stop it unfolding itself. Here’s how the dieline looks along with a finished box (we can cut our own packaging inserts too!).

Hopefully if you’ve got this far down the page you’ve found this interesting, possibly even fascinating. If it has inspired you with some ideas for creations from theatrical props to malteser-flingers then feel free to run your ideas past us and grab a zoom slot or get in touch with our contact form.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |