Making ‘flat-pack’ style items is one great application of laser cutting so when one’s wife looks at fancy tea racks for storing the inordinate quantity of tea you have you just knows what’s coming next.

And there it is and who could dare refuse that subtlest of commands so here we go. A sheet of 3mm MDF is all that’s required plus some paint to make it look smart. It’s all in the measurements to make sure that everything lines up and that when it slots together that everything is tight, although you can always use glue where needed, even MDF isn’t a perfectly consistent thickness, although it’s close.

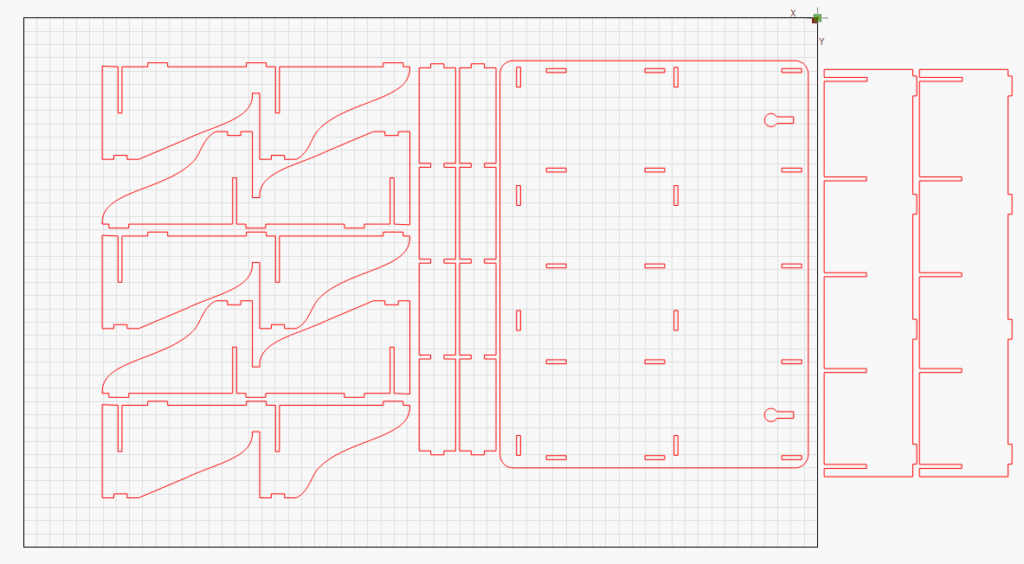

Getting the design and alignment correct isn’t as fiddly as you might think as long as you have a logical approach. It’s the deciding of how to break it down into flat shapes which takes a little longer. Once that’s done then it’s mostly a question of positioning slots and tabs and making sure you have your kerf set correctly. Kerf is essentially ‘the thickness of your blade’ when cutting things precisely. In this case it’s around 0.15mm, the diameter of the laser spot plus a small margin.

Once the design is sorted it’s a simple matter of lasercutting it from the MDF sheet and slotting it all together with the gentle persuasion of a rubber mallet to help with any of the tighter slots. A couple of coats of paint and it;s good to go. The design had keyslot in it for slipping onto screw heads but these are actually held up with nano tape which is brilliant stuff and grips most surfaces like a fiend while also being removable with no damge in most cases.

If you have an idea for items you want created then why not book a zoom call to have a chat about it or use our contact form if you prefer to get the ball rolling.

©2023 Surefyre Laser Design Ltd

info@surefyre.com

01788 247047

Trustpilot

Registered in UK 14588139

Registered for VAT 432696087

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

*** Please bear in mind that over the Christmas period postage may take longer, especially for smaller items that are not sent by tracked delivery. Allow a few extra days for delivery during this period *** Dismiss